- PC Automation

- Bunker Delivery Note (software option)

- 4 & 6" Positive Displacement Meters (Fuel Meters)

- 8 & 10" Positive Displacement Meters (Fuel Meters)

- DN32 Engine Room blender

- DN50 Static Mixer (homogenous fuel)

- Heavy Duty Fuel Pumps

- Pressure/Vacuum Valves

- Flame Arresters

- • One-piece construction prevents product leakage

- • Self Draining Housing prohibits condensate from seating surface

- • Simple installation & maintenance

- • Valve protection from freezing, binding and clogging

- • Optional pipe-away relieves vapors through a flanged connection

- • Utilized tube bank design

- • Maximum protection and efficiency with minimum pressure drop

- • Wide range of standard construction materials

- • Quick, easy inspection and maintenance due to simple removal of tube bank

- • Complete range of sizes from 2" through 12"

Go4 PC Automation - Brochure

The Go4 Automation Control and Monitoring system continuously receive information from the Go4 Bunker Monitor and use advanced proprietary control algorithms to make the necessary adjustments on the blender to adjust the exact amount of feed stock (MGO/MDO/ADDO) to be added to the HFO, to meet the ISO8217 specification of the finished/blended product.

The data is continuously accumulated in the database and can be retrieved at the end of the batch for print-out of a Bunker Delivery Note (BDN), showing all pertinent information regarding the viscosity at reference temperature (50°C).

Go4 Bunker Delivery Note (S/W option) - Brochure

The Go4 Bunker Delivery Note is a software option for the PC automation system. The option requires a PC with Windows and Excel 2007 or higher (not part of the supply).

The software will print out Batch reports in the form of a customized Bunker Delivery Note with information about the supplier, receiver, date, time, place, quantity, quality and viscosity (@50°C reference temperature).

The viscosity data for the supply is also shown as a graph covering the time used for the delivery.

Go4 4" and 6" Positive Displacement Meter - Brochure

The Go4 P.D. Flow meters for 4” or 6” have Flow Rates up to 4,000 l/min with an Accuracy ± 0,1%.

The counter permits reading and setting of parameters for :-• Presetting

• Totalization

• Linearization of the meter’s error curve

• Transmission of data

• Readings in m³ or litres

There are two models to choose from depending on the application; the PDM 400 and the PDM 600.

Go4 8" and 10" Positive Displacement Meter - Brochure

The Go4 P.D. Flow meters for 8” or 10” have Flow Rates up to 15,000 l/min with an Accuracy ± 0,1%.

The counter permits reading and setting of parameters for :-

• Presetting

• Totalization

• Linearization of the meter’s error curve

• Transmission of data

• Readings in m³ or litres

There are two models to choose from depending on the application; the HPDM 1000 and the HPDM 3000.

Go4 DN32 Engine Room blender - Brochure

The Go4 DN32 - Mechanical Fuel Oil Blender has a

Capacity of 3,6 – 7,8 m³/h and range 5-95%.

To save cost, many vessels are blending their daily consumption of fuel in a Day Tank where the components are intermixed as thoroughly as possible.

This tedious method can now be substituted by In-line blending, where the components are fed in a controlled, simultaneous flow, in the correct ratios, to the DN32 which makes a high quality finished blend.

It is a quick and easy process taking place during normal daily operation, without the extra storage tanks and complicated logistic required when doing batch blending.

The Go4 Blender makes a perfect “Viscosity-Blend” with an accuracy of ±2% to the specification.

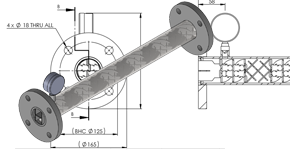

Go4 Static Mixer Unit DN 50/100/150 - Brochure

If the requirement is a very homogeuos product blend, the Go4 Static Mixer Unit is the solution.

Fitted with standard DIN flanges (ANSI on request), the unit can easily be inserted into an existing pipeline without major changes.

The unit guarantees an effictive blend through constant turbulence.

The unit is equipped with a Pressure Gauge to monitor the pressure in the pipe.

Go4 HD 201 Heavy Duty Fuel Pump - Brochure

The Go4 HD 201Heavy Duty Cast Iron Pumps have a Capacity of up to 150 m³/hour @ 8 bar.

They are specifically designed for difficult applications involving high viscosity liquids and are known by their sturdy and simple construction and reliable operation.

The modular design of the pumps allow a large number of pump configurations for specific tasks. The pumps can also do reversible pumping, as the direction of flow is determined by the rotation of the motor.

No matter what the application, the Go4 HD Pump is built tough and get the job done without constant worries about pump failure and costly repairs.

The pump can be provided with a relief valve to prevent overpressure and/or a temperature sensor to monitor temperature build-up.

Pressure / Vacuum Valves - Brochure

The valves are ideally suited for a variety of tank storage and product conservation applications. It is applicable for the chemical, petroleum, petrochemical and waste treatment industries.

This conservation valve can be utilized at the end of the line allowing vapors to escape into the atmosphere. An optional closed vent design is available to pipe-away hazardous vapors not allowed to be readily released.

They are easy to install and completely compatible with existing pipes, valves and tank fittings.

Flame Arresters (horizontal or vertical) - Brochure

The Flame Arresters are designed to provide a positive flame stop in gas piping systems. They offer maximum flow capacity and are specifically designed to prevent liquid accumulation in the tube bank assembly.

Flame Arresters are generally installed with pressure-vacuum vents, or in-line free vent to atmosphere. The tube bank design consisting of a spiral-wound crimped ribbon around a solid core, maximize flow capacity with minimum pressure drop.

Available with flat face flanges for aluminum or raised face flanges for cast steel and stainless steel to match ANSI, DIN, or JIS 10K specifications.